Chemical recycling processes can be applied to e.g. by-products of scrap metal recycling, so-called shredder light fractions. Waste plastics from the construction sector, e.g. bromine-containing expanded polystyrene, or fractions from the recovery of waste electrical and electronic equipment may also be chemically recycled. For these and other fractions, the "HydroCycling" project is developing concepts for their mechanical processing and subsequent catalytic conversion into petrochemical raw materials and basic chemicals.

HydroCycling - from laboratory to demonstrator

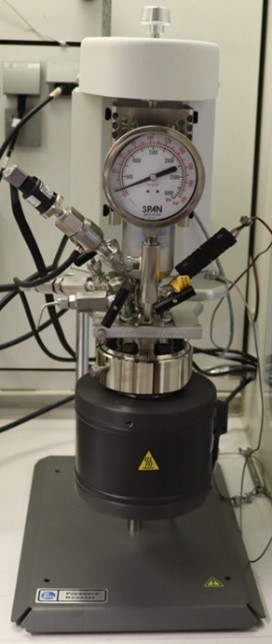

The industry currently favors two chemical recycling routes: One is via the pyrolysis of used plastics and the use of the pyrolysis oils as petrochemical raw materials. The second route is gasification and the production of petrochemical polymer building blocks from synthesis gas. "HydroCycling" also attempts to largely preserve the molecular structures of used plastics and use hydrogenation to obtain petrochemical raw materials and basic chemicals. Catalytic hydrogenation of polymers has been scientifically described many times. Depending on the catalysts used and the operating conditions, different polymers have been converted in pure form or in mixtures, e.g. with refinery streams. In "HydroCycling", the influence of the composition of available, real plastic waste on hydrogenation will also be investigated. Pre-processing steps will be developed experimentally. The aim is to remove interfering foreign substances from the plastic waste to obtain usable input materials for the “HydroCycling” process. These will be converted into hydrocarbon mixtures by catalytic hydrogenation on a laboratory scale. Product work-up and utilization will be simulated in combination with a commercial “HydroCycling” plant at a refinery or petrochemical site. An important objective is to develop a concept for a demonstrator in a follow-up project. The process developed in individual steps at laboratory scale could be combined, its operation could be demonstrated and first product samples be produced.

Realization and holistic assessment

In addition to this work, a comprehensive assessment of the “HydroCycling” concept from a techno-economic, ecological, regulatory, and patent law perspective is being carried out as part of the project. This is a prerequisite for industrial implementation of the new process.

Progress and Results of the First Project Phase (Status April 2025)

• Identification of access points to existing post-consumer plastics from various waste streams and development of a logistics concept for supplying feedstock to the site of a commercial HydroCycling facility. Through mechanical processing of waste source streams, the polymer content must be concentrated and the fluctuating compositions balanced. Only with a consistent, specification-compliant quality will post-consumer plastics be reliably recyclable in industrial HydroCycling plants.